挑戦

Challenge

培った技術を生かしながら新たな分野へ、また、常に同じものではなく一歩進んだものづくりに挑戦しています。

エネルギー効率の良い製品やリサイクル可能な製品といった環境配慮型製品の開発もその一環です。

多様性

Diversity

風通しの良い社風で社員が自由に発言できる会社を目指しています。

さまざまな観点や考え方を取り入れることで、工業炉・ヒーター製造のトップランナーとして企業の多様性を育てます。

信頼性

Reliability

高熱高温分野に長年携わってきた経験と知識により、多くの信頼を獲得している

と自負しております。

また、技術を高めることでより高い信頼性を得られる企業となるべく努めています。

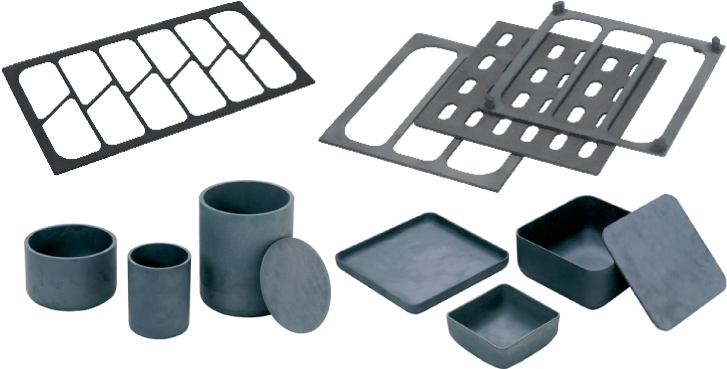

工業炉

電気炉や燃焼炉といわれる工業炉は、セラミック、電子部品、金属、ガラス、粉体などを所定の温度で加熱、焼結したり、溶解、熱処理するための装置です。

当社はこのような熱処理のための工業炉およびその関連設備の設計・製作に豊富な実績と、工業炉に必要な発熱体、耐火物の総合メーカーとして高度な複合技術を持ち、小型試験炉から産業用大型装置までのあらゆる分野に供給しております。

エレマ発熱体

エレマ発熱体は高純度SiCから成り、炭化けい素発熱体はわが国で最初に市販されました。

1927年(昭和2年)市販以来、豊富な経験にもとづいて鋭意研究を重ね、独自の開発技術と内外の技術を結集して品質の向上・改良に努め、ここに業界最大の生産規模と共に最高品質の製品としてご好評いただいております。

エレマ抵抗器

当社は1961年(昭和36年)以来、セラミック抵抗器の製造販売にたずさわり、広く電力、通信、医療等各方面の技術、性能向上に寄与してまいりました。

エレマ抵抗器は高温で焼結されたセラミック抵抗器であるため、苛酷な条件のもとにおいて、高い信頼性を必要とする回路に最も適した抵抗器です。